ROLL FORMING MACHINE

TUBE MILL MANUFACTURER

Home » Company

ABOUT YANGZHOU TEW SPARE TECHNOLOGY Co.,Ltd.

TEW SPARE TECHNOLOGY Co.,Ltd. as a professional manufacturer renowned forits precision-rafted tube mill roller, electromagnetic chuck and tube mill, cold roll forming machines. As a company sets design, manufacturing, sales and after-sales service in one.From materials of machine parts selection, each part machining and treatment, whole machine manufacturing and surface painting, we carefully value all details of entire production process to make high quality products. TEW SPARE company has been devoted to manufacturing and exporting various kinds of pipe roller,electromagnetic chuck and pipe mill for over twenty years.

As soon as our company was established we have put a tremendous amount of our focus into our Research and Development (R&D) teams in order to maintain the level of excellence that is prevalent throughout the whole world! To diversify our products for our customers, we are now manufacturing many different types of products, such as tube mill roller, pipe mould, working roller, tube mill,pipe mill, electromagnetic chuck and many more.

The process typically involves several steps:

- Uncoiling: The coil of metal strip is uncoiled and fed into the machine.

- Leveling: The strip is flattened and leveled to ensure a uniform thickness.

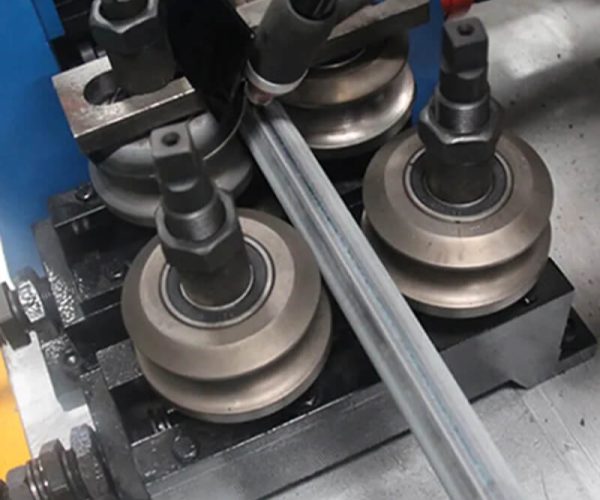

- Forming: The strip is passed through a series of rollers in the die, which gradually shape it into a cylindrical form.

- Welding: The edges of the formed tube are brought together and welded using high-frequency or resistance welding.

- Sizing: The welded pipe is sized to its final dimensions.

- Cooling: The pipe is cooled to room temperature.

- Cutting: The pipe is cut to the desired length.

Key Components of a Welding Pipe Die:

- Rollers: These shape the metal strip into a tube.

- Mandrel: This supports the inside of the tube during the forming process.

- Welding electrodes: These provide the electrical current for welding.

- Cooling system: This cools the welded joint to prevent distortion.

Applications of Welded Pipes:

Welded pipes find extensive use in various industries, including:

- Construction: For structural support, piping systems, and scaffolding.

- Automotive: For frames, axles, and exhaust systems.

- Mechanical engineering: For hydraulic cylinders, transmission shafts, and tubing.

- Oil and gas: For pipelines and drilling equipment.

How to select the right magnet modes?

When the suction material temperature is lower than 1009C, please use the normal temperature type. When itexceeds 100°C, please select the high temperature type.

When the power continuity rate exceeds 60%, please use high-frequency type.

When lifting materials underwater, please use submersible type (dive depth 100m). Submersible electromagnetshave the same parameters as the normal temperature type. Therefore, the sample is not listed. If the user requires asubmersible type, please specify when ordering.

- Environment temperature: normal temperature -5C ~ 40 C, high temperature -5 C ~ 80 C. The altitude doesnot exceed 2000m.

- Equipment matching: The power (current) of the rectifier control equipment is more than or equal to the sum ofthe cold power (current) of single or multiple units.